3D SCAN Vision System

| Characteristics |

· Structural Light-Based Precision 3D Scan Vision System Using Beam Modules and Industrial Cameras · Breakthrough noise cancellation technology · Convenient User-Interface Features · Simple application of settings, stable pattern matching (Patmax) | |

| 3D SCAN Application of sensors |

· 3D Pattern Matching of Object · Quality inspection of the object (dimension and shape defect inspection) · Specification inspection of the object: Vehicle roof specification inspection, tailgate specification inspection · 3D position correction system: vehicle glass mounting system, tire mounting system | |

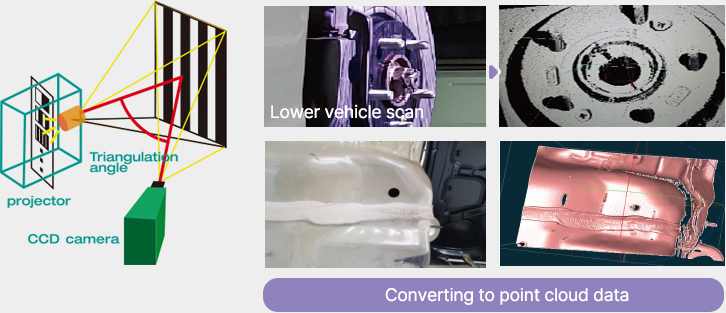

| Measurement Principles |

| |

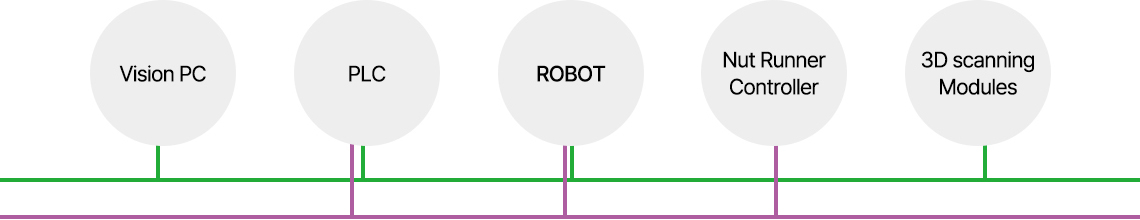

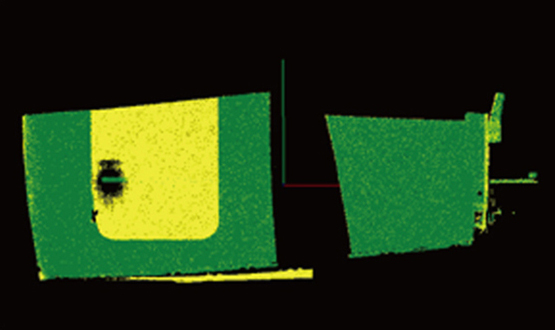

LAY OUT

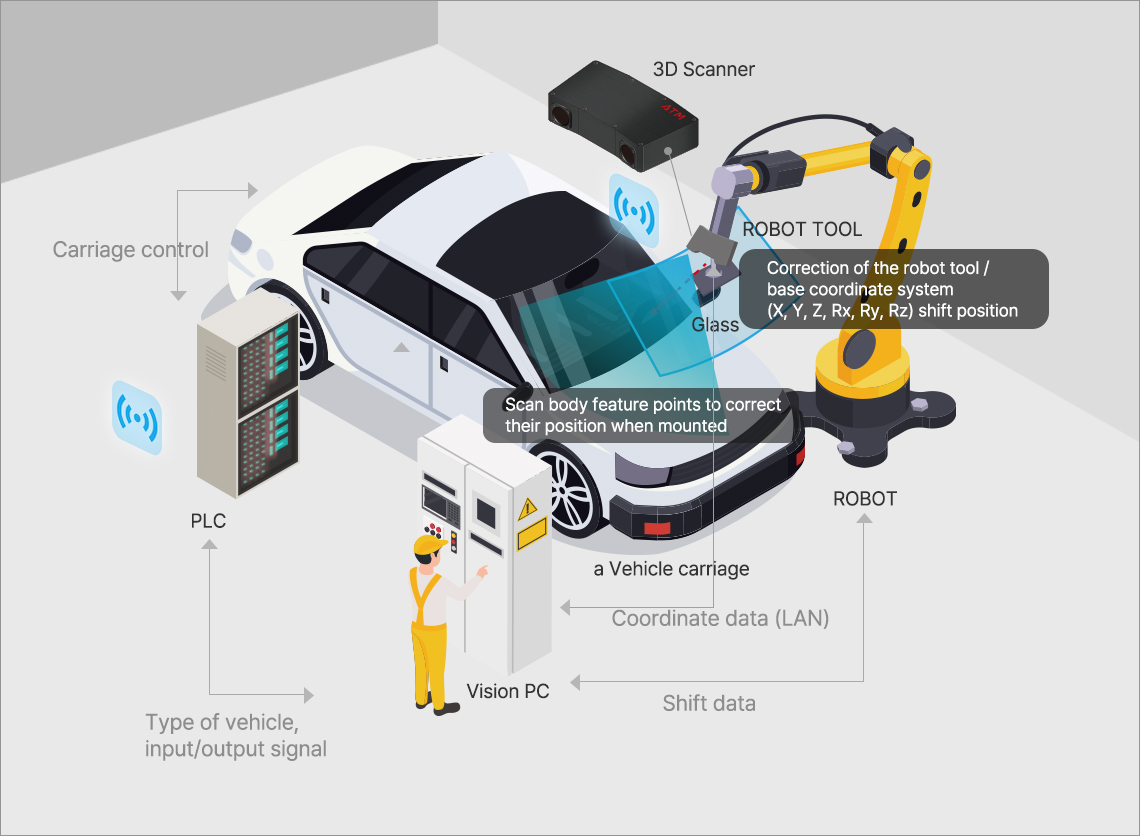

3D SCAB Position Correction Vision System

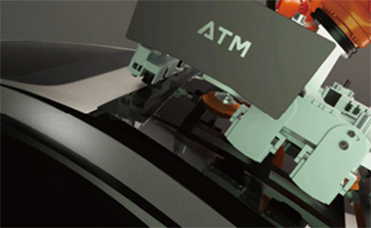

· Calculate the amount of movement (Δx, Δy, Δz, ΔRx, ΔRy, ΔRz) compared to the reference vehicle by applying a matching algorithm

· Transmit the calculated amount of movement to the industrial robot, apply it as an offset, and mount it

· Apply technology to scan at least three vehicle frames and merge them into a single pointer cloud

· The error rate is low and the movement calculation is significantly better even if the position of the vehicle to be installed is tilted or rotated.

· When measuring 3D SCAN, position correction rate is better than 2D vision

Application of 3D scan Position Correction Vision System

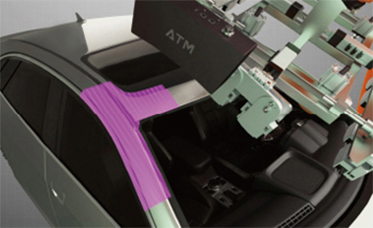

· AITZ 3D Glass Mounting System: 3D Area Scan Sensor measures the body frame on which the glass will be mounted to extract point cloud data

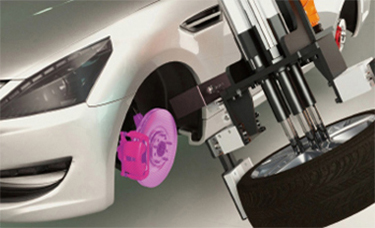

· AITZ 3D Tire Fastening System: 3D Area Scan Sensor measures the wheel hub where the tire will be mounted to extract point cloud data

3D scan position Correction procedure

|

Create a Mast |

|

Position SCAN |

|

Perform ICP Matching |

|

Calculate the amount of movementCalculate the amount of movement (△X,△Y,△Z,△Rx,△Ry,△Rz) |

|

Transfer to RobotTransfer to Robot |

|

Mounting procedure |

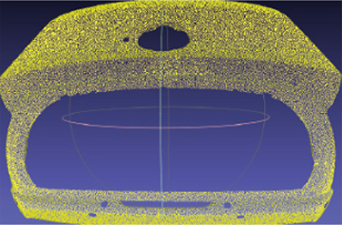

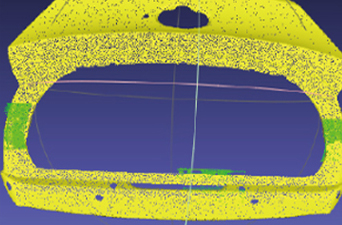

Generating mast

Generating mast

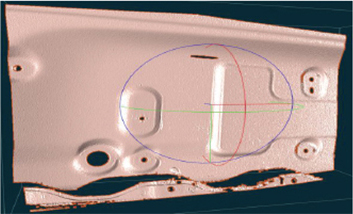

Image of overlap between scan data and mast

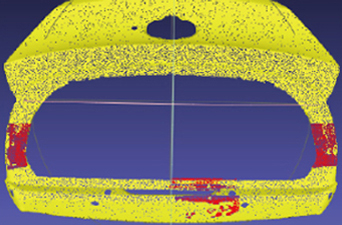

Image After ICP Matching (calculating the amount of movement)

Communication example

3D Specification Inspection System

· Implementation of specification inspection in 3D vision that is not possible with 2D vision

· Multi-dimensional response in one process

· Application of technology to measure two loops and merge them into one pointer cloud data

Application of 3D Scan Specification Inspection Vision System

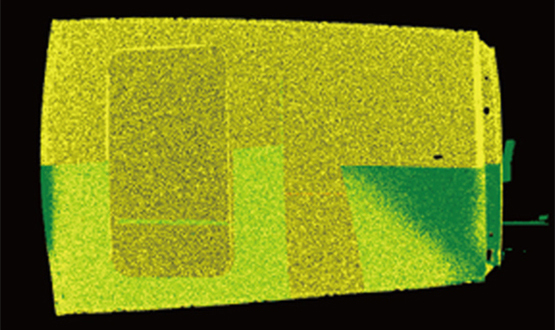

· AITZ 3D roof specification inspection system: 3D area scan sensor detects vehicle roof curvature to inspect specification

· AITZ 3D Tailgate Specification Inspection System: Vehicle Number by Country in Same Model

3D scan specification inspection procedure

|

Creat Mast |

|

3D SCAN |

|

Perform ICP Matching |

|

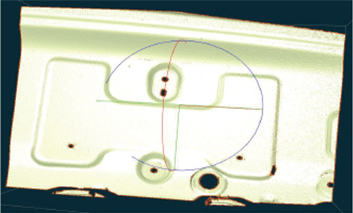

Map Extraction and Hall Detection or Fitness and Overlap Calculation Map Extraction and Hall Detection or Fitness and Overlap Calculation |

|

Determining Specifications |

|

Mounting Procedure |

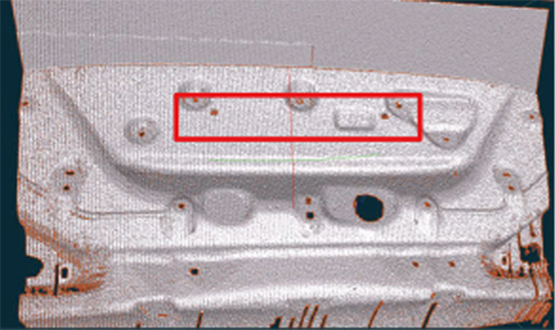

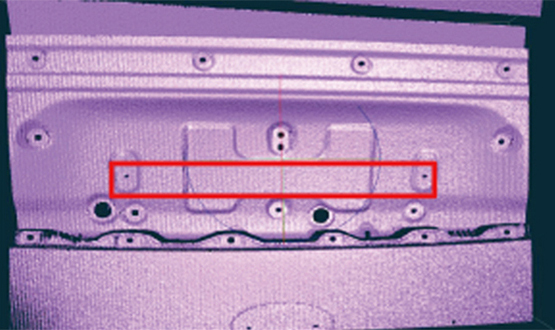

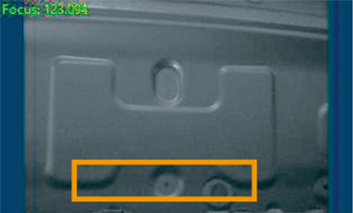

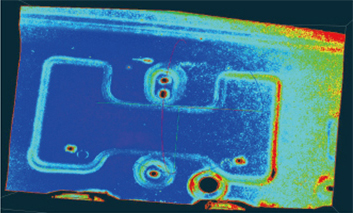

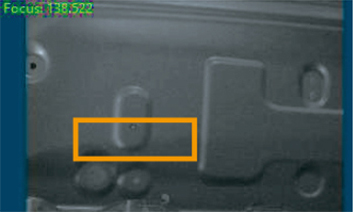

3D SCAN images

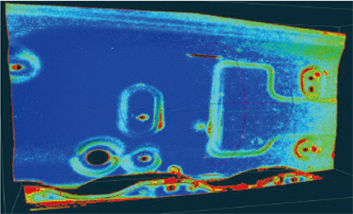

3D SCAN hole detection image

|

|

|

|

|

|

|

|

| * Curvature map: blue if you are close to the sensor, green, red as you move away | |||