AITZ Tire Mounting Vision System

The AITZ Tire Mounting Vision System combines AITZ 3Ds and AITZ vision software developed by itself through the technology of ATM only

An innovative complement to the completeness and margin of error compared to conventional tire mounted vision systems.

Accurately measure the rotation and movement deviation of the wheel hub so that the tire is installed in the correct position.

Characteristics

- Accurate and fast body deviation measurement with AITZ 3Ds (time required: around 1 second)

- Can be mounted by measuring deviation even if the wheel disc rotates and tilts.

- Normal measurements can be made without some disturbance interference and external lighting

- High accuracy allows normal mounting on moving conveyor rather than stationary conveyor

AITZ 3Ds

- Structural light-based ultra-precision 3D scanning sensor using beam modules and industrial cameras

- Ultra-fast processing power with scan speed of 0.2s and data processing speed of 0.5s

- Optimized for product positioning and calibration in the automated process

AITZ Vision Software

- Our Algorithm-Based Program

- Convenient User-Interface

- Communicate with I/O to optimize connectivity

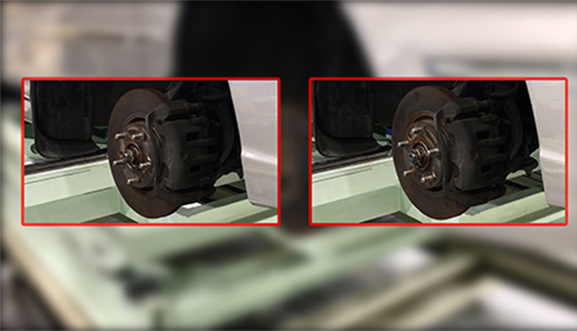

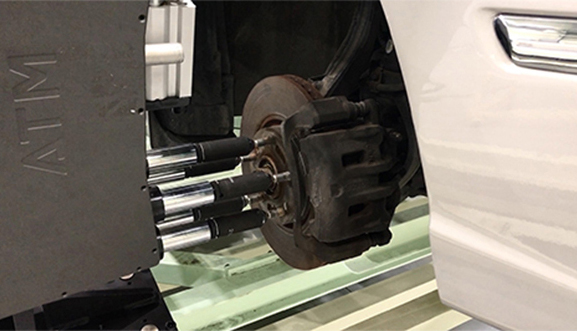

3D SCAN allows normal mounting even if wheel disc rotation occurs

AITZ 3Ds accurately measure the rotated value even if the wheel disk rotates so that it can be mounted normally.

Normal mounting via 3D SCAN even if wheel disc tilting occurs

ven if the wheel disk is tilted during conveyor movement, the tilted angle is measured through the 3D SCAN to enable normal installation.

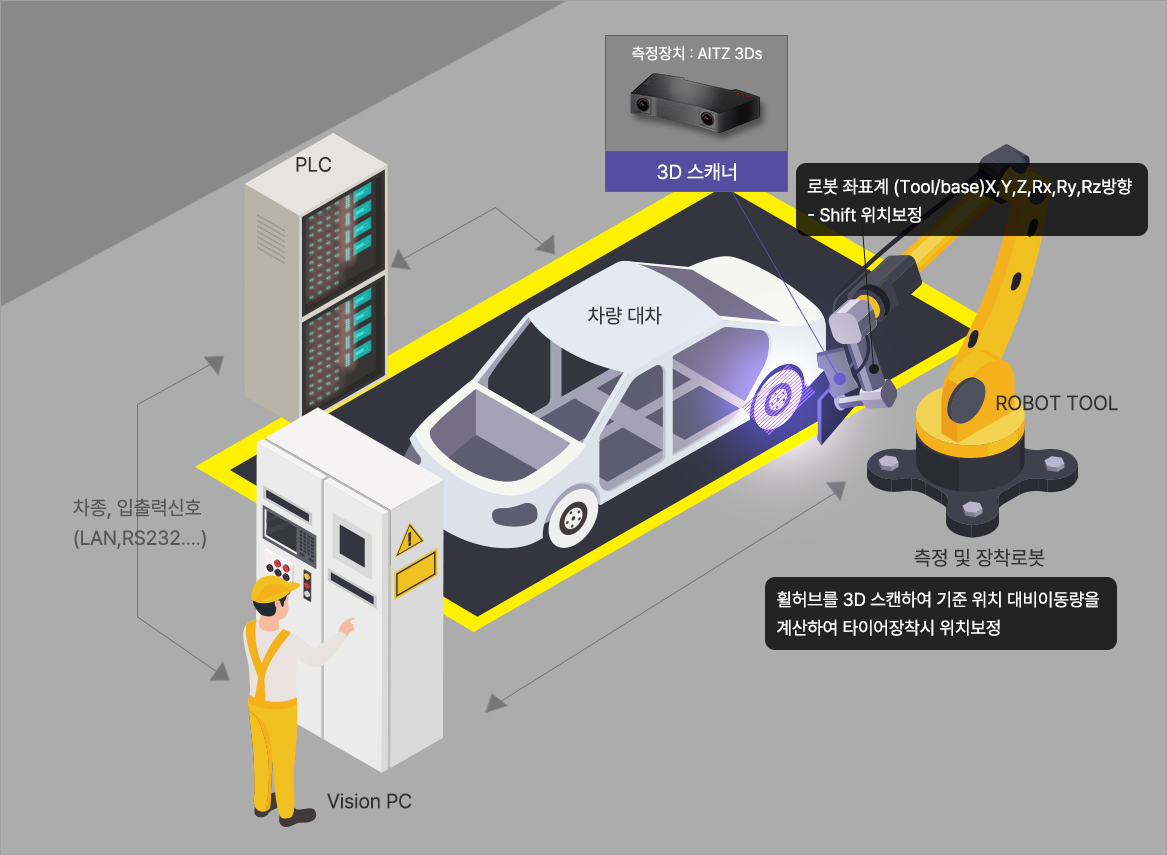

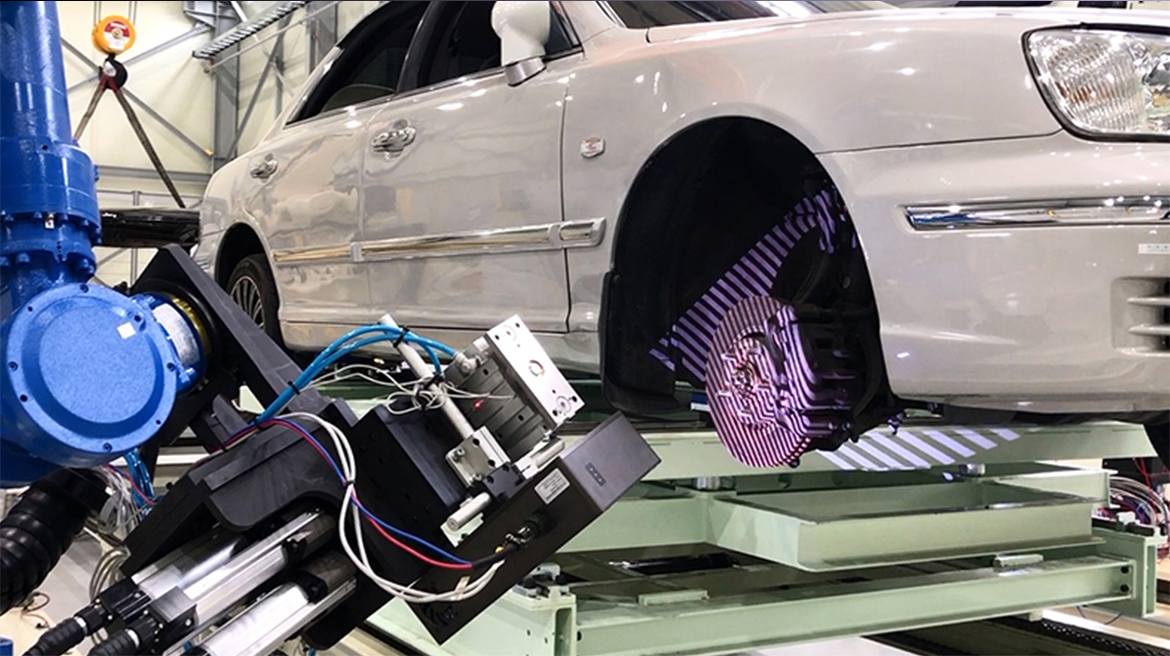

Tire mounting configuration diagram

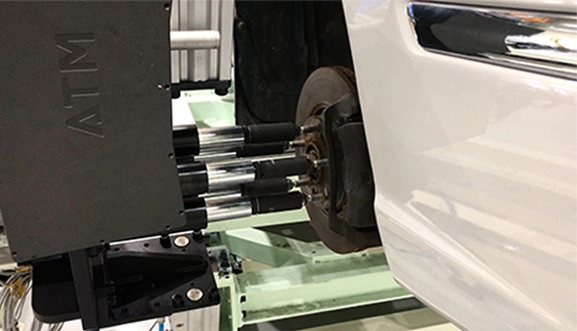

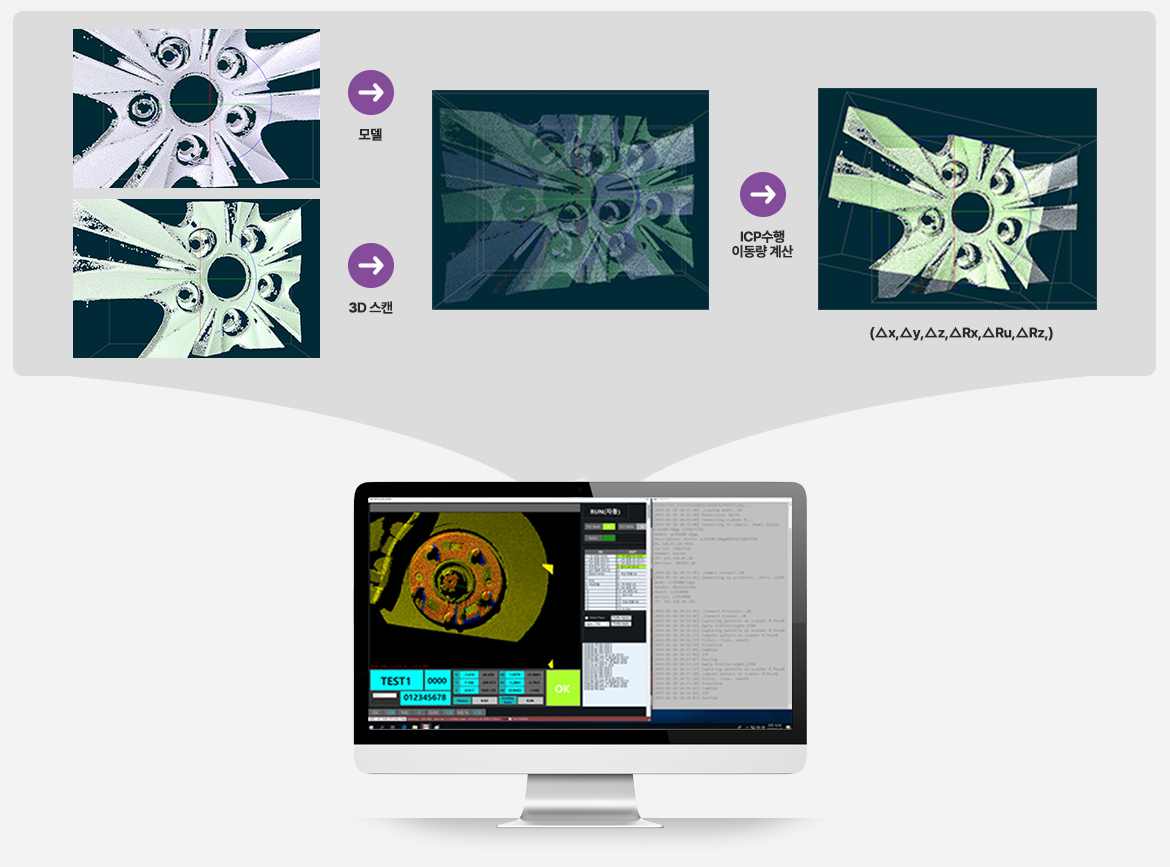

Tire mounting procedure

AITZ 3Ds Scan Wheel Hubs

By performing ICP matching, the amount of movement compared to the reference position is calculated and the position deviation is transmitted

Move to the tire mounting position and carry out normal mounting